Core Functions of Medium Voltage Switchgear: Control, Protection, and Safety

MV switchgear forms the foundation for most industrial and utility power setups, handling electricity at voltages ranging from around 1,000 volts all the way up to 36,000 volts. What makes these systems so important? Well, they basically do three main things: control when power flows, protect against problems, and keep everyone safe. When something goes wrong like a short circuit happens or there's an overload situation, the gear kicks in fast. The IEEE C37.20.2 guidelines actually specify how quickly these systems need to respond, often isolating bad parts of the system in just fractions of a second before anything gets damaged or someone gets hurt. This rapid response time is what keeps factories running smoothly day after day.

Understanding the Primary Role of Medium Voltage Switchgear in Power Distribution

MV switchgear acts as a traffic controller for electricity, directing power to operational circuits while isolating compromised ones. This selective tripping maintains uptime in healthy parts of the system—an essential capability in sectors like manufacturing, where unplanned outages cost over $740k/hour (Ponemon 2023).

How Control and Protection Functions Prevent System Failures

Advanced circuit breakers paired with protective relays continuously monitor current patterns. When anomalies exceed safe thresholds, they trigger disconnection in under 50ms in modern systems. This rapid response reduces thermal stress on transformers and cables by up to 92% compared to legacy protection methods.

Monitoring and Safety Interlocks as Critical Operational Features

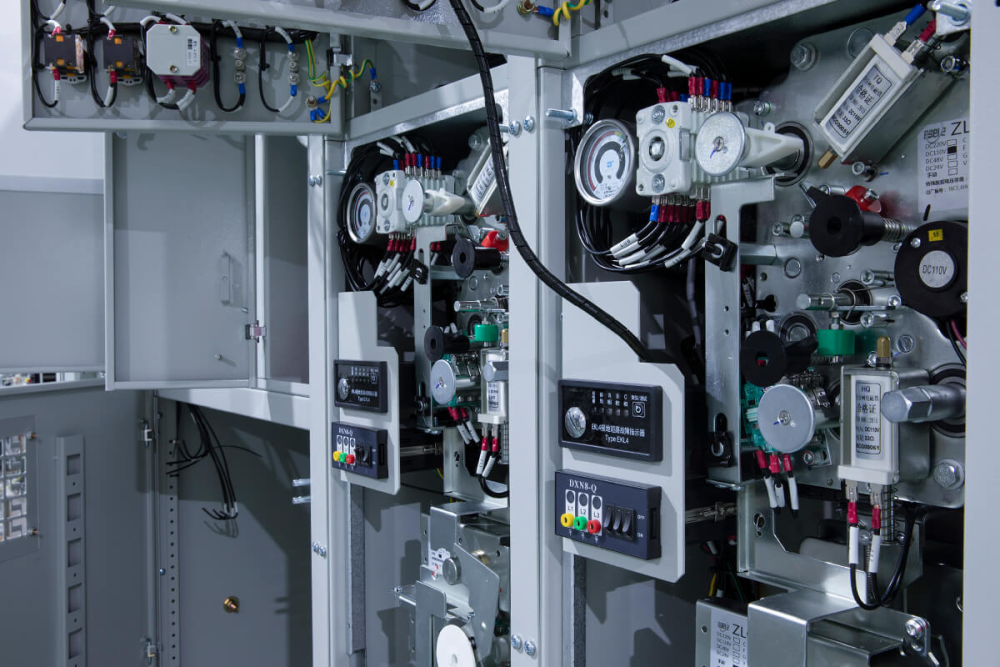

Modern MV switchgear integrates key safety technologies:

- Gas density sensors to detect SF6 leaks in gas-insulated systems

- Mechanical interlocks that prevent access to live compartments

- Remote monitoring ports enabling predictive maintenance

These features reduce arc flash incidents by 67%, according to NFPA 70E field reports.

Industry Data on Outage Reduction Due to Effective MV Switchgear Deployment

Facilities using smart MV switchgear with IEC 61850 communication protocols experience 41% fewer outages annually. Real-time diagnostics allow operators to resolve 83% of emerging issues before escalation, transforming maintenance from reactive to proactive.

Key Power Components: Circuit Breakers, Switches, and Busbars

Circuit Breakers in MV Switchgear: Vacuum vs. SF6 Technologies and Applications

Modern circuit breakers can stop fault currents as high as 40kA in just 3 to 5 cycles of operation. For indoor setups, vacuum breakers have become the go to choice because they take up less space and need minimal upkeep. Outdoors is a different story though, where SF6 breakers still hold their ground thanks to better performance when dealing with arcs in tough weather conditions. Looking at recent market trends, vacuum tech makes up around 72 percent of all medium voltage installations below 38kV these days. This shift towards vacuum solutions seems to be part of broader efforts across the industry to make electrical grids greener and more sustainable overall.

Busbar Design, Thermal Management, and Reliability Under High Load

Copper or aluminum busbars form the conductive core of switchgear. Their cross-sectional area and material interfaces determine current capacity, with advanced designs achieving 96% efficiency at 4kA loads. Optimized spacing and passive cooling reduce hotspots, extending lifespan by 30–40% versus traditional layouts.

Switches and Isolators: Ensuring Safe Operation and Maintenance Access

Disconnect switches enable manual isolation for maintenance without full shutdowns. Safety interlocks prevent accidental re-energization during servicing—a feature that reduces arc-flash incidents by 89% in compliant installations (NFPA 70E 2023). Modern rotating cam isolators achieve emergency cutoffs in less than 0.5ms.

Grounding Mechanisms and Their Critical Role in Personnel Safety

Integrated grounding switches discharge trapped energy before maintenance begins. Transient voltage suppression limits step potentials to <1.2kV, meeting IEEE 80 requirements. Properly grounded systems reduce fatal electrical accidents by 94% in industrial environments (OSHA 2022).

Protective and Monitoring Devices: Relays, IEDs, and Instrument Transformers

Protective relays and Intelligent Electronic Devices (IEDs) for fault detection

Protective relays act like the brain inside MV switchgear systems, spotting problems when there's an imbalance in current flow. They can catch issues like ground faults at around 5% or more, plus detect those dangerous phase-to-phase short circuits all within just three electrical cycles. Newer Intelligent Electronic Devices come equipped with arc flash detection features that cut down on dangerous energy levels during incidents by about 85 percent according to recent safety reports from 2023. These days, many grids are adapting their protective settings automatically based on real time changes happening across the network. This becomes especially important when dealing with power systems where renewables make up more than thirty percent of total generation capacity.

IEC 61850 and communication protocols enabling smart protection coordination

IEC 61850 makes it possible for devices to talk to each other smoothly via what's called process bus architecture. This cuts down on all those wires by around 70 percent and lets equipment communicate directly with each other in under ten milliseconds. Power companies that have adopted this system are seeing something remarkable too fault detection happens about 92% quicker in their looped network setups according to field reports from several major European utilities. Then there's GOOSE, which stands for Generic Object Oriented Substation Event. What does that mean practically? Well, when problems occur, GOOSE can trip multiple circuit breakers at once so fault currents stay well below dangerous levels even in crowded city power grids where current limits need to be strictly controlled.

Current and voltage transformers (CT/VT): accuracy, burden, and integration

Class 0.2 CTs maintain ±0.2% ratio error up to 120% rated current—essential for differential protection requiring <2% measurement mismatch. Low-burden VTs (<1VA) avoid saturation during voltage sags below 70% nominal, ensuring accurate relay operation. Anti-resonance filters in modern designs suppress harmonic distortion (THD >8%) from inverter-based resources.

Digital sensors and next-gen instrument transformer trends in MV switchgear

Optical sensor-based instrument transformers offer 0.1% accuracy across a wide frequency range (10Hz–5kHz), enabling detection of high-impedance faults undetectable with analog systems. The latest models integrate SF₆ density monitoring and fiber Bragg grating thermal sensing, reducing maintenance interventions by 40% in demanding environments.

Enclosures, Surge Protection, and System Resilience

Switchgear enclosures and compartmentalization for component protection

MV switchgear enclosures provide critical defense against environmental and electrical hazards. Compartmentalized designs use fire-resistant barriers to isolate circuit breakers, busbars, and cables, reducing arc flash risks by 74% (Fortress Protective Buildings 2023). Sealed units meet NEMA 3R or IP54 ratings, protecting against dust and moisture in outdoor installations.

Surge arresters and transient overvoltage protection in medium voltage networks

Surge arresters protect against transients from lightning and switching events—responsible for 23% of MV system failures (SecuritySenses 2022). Zinc-oxide varistors clamp voltage spikes to ±1.5 p.u. within nanoseconds, shielding sensitive electronics. Coordinated surge protection combined with proper grounding reduces DC circuit fault risks by 60%.

Modular designs and serviceability improvements in modern MV switchgear

Modular architectures support faster maintenance via slide-out breaker cassettes and tool-less busbar access. Standard cubicle widths (typically 800mm) allow incremental upgrades without full replacement. Front-accessible terminations and RFID-tagged components reduce mean repair time (MTTR) by 35% (2024 Industrial Switchgear Report).

Smart Integration and Future Trends in Medium Voltage Switchgear

IoT and Smart Circuit Breakers: Real-Time Monitoring and Predictive Maintenance

IoT-enabled sensors and AI analytics allow continuous monitoring of temperature, load, and insulation health. Predictive maintenance powered by this data cuts unplanned downtime by 35% in utility networks (Future Market Insights 2023). Smart breakers now self-adjust protection settings based on real-time load patterns, improving responsiveness and reducing human intervention.

Digital Substation Architecture and Automation Benefits

IEC 61850 has standardized communication between relays, IEDs, and control systems in digital substations. This interoperability enables coordinated fault isolation and automatic load transfers, resulting in 25% faster responses than legacy systems. Digital twins of switchgear assemblies also support scenario simulation and optimized maintenance planning.

Sustainability Trends: SF6 Alternatives and Eco-Friendly Switchgear Designs

The push against SF6 emissions, which pack about 23,500 times the punch of regular carbon dioxide, has really sped things up for vacuum and solid insulated switchgear options. Industry reports from last year show something interesting too: companies looking for SF6 free alternatives saw their market grow by around 40 percent just since 2021. Now we're seeing all sorts of hybrid approaches take off. Some use plain old dry air while others mix in fluoronitrile compounds. Manufacturers are also getting creative with recyclable materials for equipment housings and implementing better cooling systems that save power. All these innovations help facilities work toward those net zero goals everyone keeps talking about these days.

FAQ

What is the main function of medium voltage switchgear?

Medium voltage switchgear primarily functions to control power flow, protect against system faults, and ensure safety in power distribution systems.

How does modern MV switchgear improve system reliability?

Modern MV switchgear improves system reliability by enabling fast isolation of faults, real-time diagnostics, and predictive maintenance, resulting in fewer outages and reduced downtime.

What technologies are used in MV switchgear to enhance safety?

Technologies like gas density sensors, mechanical interlocks, and remote monitoring ports are used to enhance safety and reduce incidents like arc flashes.

How do vacuum and SF6 circuit breakers differ in MV applications?

Vacuum circuit breakers are preferred for indoor applications due to space and maintenance advantages, while SF6 breakers are favored for outdoor environments where they perform better under harsh conditions.

Table of Contents

- Core Functions of Medium Voltage Switchgear: Control, Protection, and Safety

- Key Power Components: Circuit Breakers, Switches, and Busbars

-

Protective and Monitoring Devices: Relays, IEDs, and Instrument Transformers

- Protective relays and Intelligent Electronic Devices (IEDs) for fault detection

- IEC 61850 and communication protocols enabling smart protection coordination

- Current and voltage transformers (CT/VT): accuracy, burden, and integration

- Digital sensors and next-gen instrument transformer trends in MV switchgear

- Enclosures, Surge Protection, and System Resilience

- Smart Integration and Future Trends in Medium Voltage Switchgear

- FAQ

EN

EN

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

AR

AR

BG

BG

CS

CS

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

BN

BN

KN

KN

LO

LO

LA

LA

PA

PA

MY

MY

KK

KK

UZ

UZ