Improved System Reliability and Operational Continuity

Medium voltage (MV) switchgear strengthens industrial power systems by addressing three critical reliability factors: instability prevention, downtime reduction, and redundancy optimization.

How Medium Voltage Switchgear Prevents Power Instability

MV switchgear uses microprocessor-based relays to detect voltage fluctuations and imbalances, isolating faults within 50 milliseconds—significantly faster than traditional systems. This rapid response prevents cascading failures, which cause 42% of industrial power interruptions according to a 2023 grid stability analysis.

Case Study: Reducing Downtime in a Steel Plant with MV Switchgear

A North American steel mill upgraded to MV switchgear with IEC 62271-200 certified circuit breakers. Over 18 months, the facility reduced unplanned outages by 35% and improved fault response accuracy to 99.2%, as detailed in the 2024 Industrial Power Systems Report.

Strategy: Implementing Redundant Configurations for Maximum Uptime

Dual-bus MV switchgear designs allow seamless power rerouting during maintenance or faults. A tiered redundancy approach includes:

- Primary and backup transformer feeds

- Automatic Transfer Switches (ATS) with <100ms transition

- Remote-operated disconnects for safe isolation

This strategy supports >99.95% uptime in heavy industries—equivalent to just 4.3 hours of annual downtime, compared to 72 hours in non-redundant systems.

Enhanced Safety Through Fault Isolation and Arc Flash Protection

MV switchgear makes work sites safer by stopping electrical problems almost instantly and keeping dangerous arc flashes contained. When dealing with powerful electrical systems, modern equipment with arc resistant casings and better sensing tech can slash the energy released during accidents by around 80% compared to older models. Take ZSI systems for instance these clever setups actually shorten how long it takes to clear faults by about half in really important industrial settings. Field tests from recent years back up these claims showing real improvements in plant safety across the board.

Mitigating Electrical Hazards in High-Power Industrial Environments

Modern MV switchgear detects arcing faults via optical sensors that respond to light emissions within 1–2 milliseconds, while pressure-relief vents safely channel explosive energy. These systems comply with OSHA 29 CFR Part 1910.271, which mandates <8 cal/cm² incident energy in worker-accessible areas.

Case Study: Reducing Accidents in Chemical Plants Using Modern MV Switchgear

After upgrading to arc-resistant MV switchgear with current-limiting fuses, a chemical processing facility reduced electrical incidents by 75%. The system lowered incident energy to 3.2 cal/cm², enabling safer maintenance and ensuring ongoing NFPA 70E compliance.

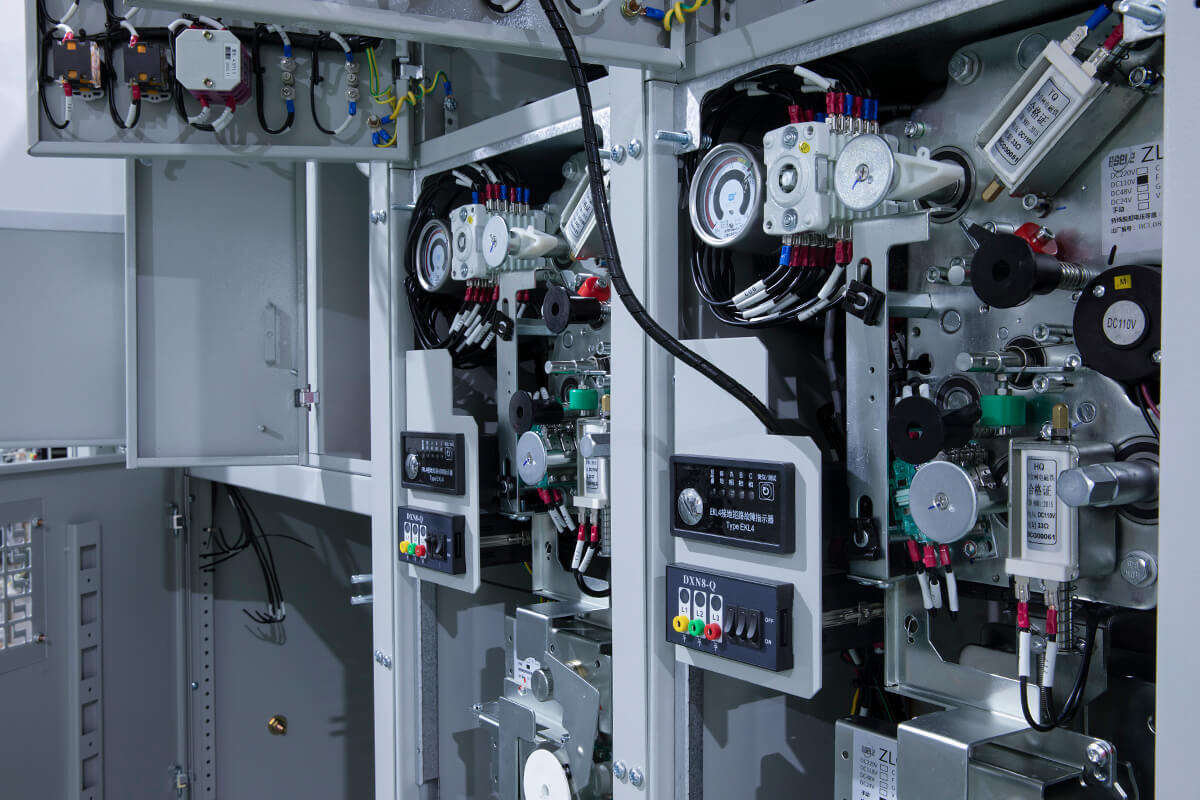

Integrating Protective Relays and Interlocks for Safer Operations

Advanced protective relays use differential current monitoring to isolate faults three times faster than traditional breakers. Leading manufacturers now include passive arc flash containment systems that operate without auxiliary power, minimizing human error during testing. Modular designs also support integration of ground-fault monitors and door interlocks without disrupting operations.

Energy Efficiency and Lower Operational Costs

Medium voltage switchgear cuts down on wasted energy because it works with higher distribution voltages, which means less heat loss from resistance in wires. According to some recent studies from Centrica Business Solutions back in 2023, when companies upgrade their infrastructure to more efficient MV systems, they can cut their need for backup power sources by almost half. This happens mainly because electricity flows better through these systems and maintenance costs go down over time. Real world results are pretty impressive too. Take a certain cement factory for instance they managed to slash their yearly energy bills by 30 percent once they installed modular MV switchgear throughout their operations. The difference was noticeable right away and kept getting better as time went on.

| Factor | Traditional Systems | MV Switchgear |

|---|---|---|

| Annual Energy Losses | 8-12% | 3-5% |

| Maintenance Frequency | Quarterly | Biannual |

| Load Management Precision | Manual | Automated |

Smart MV switchgear further cuts costs through real-time load monitoring, allowing facilities to balance energy demand with production schedules. Intelligent relays reduce peak demand charges by automatically shifting non-critical loads during high-tariff periods—lowering expenses while extending equipment life by preventing overload stress.

Scalability and Future-Proofing Industrial Power Systems

MV switchgear enables industrial operators to adapt to changing energy demands efficiently. According to the 2024 Grid Resilience Report, facilities using modular MV architectures reduced upgrade costs by 18–30% compared to fixed systems.

Modular Design of MV Switchgear for Easy Expansion

Compartmentalized construction allows operators to add breakers, relays, or monitoring modules without shutting down entire lines. This phased scalability reduces capital expenditures by 23% for expanding plants (Energy Systems Journal, 2023). Standardized busbar interfaces and pre-engineered cable chambers streamline capacity additions during scheduled maintenance.

Case Study: Scaling Power Infrastructure in a Mining Operation

A copper mine expanded its substation from 5MW to 18MW over seven years using modular MV switchgear:

| Year | Capacity Added | Downtime During Upgrade | Cost vs New Installation |

|---|---|---|---|

| 2025 | 2.5MW | 14 hours | 41% savings |

| 2028 | 4.0MW | 18 hours | 38% savings |

| 2032 | 6.5MW | 22 hours | 33% savings |

This incremental approach avoided a $2.7M full-system replacement while maintaining 99.96% uptime throughout the expansion.

Planning Flexible Power Architectures for Industrial Growth

Smart facilities are now pairing modular medium voltage switchgear with digital twin tech to get ahead of growing power demands. Take a recent case at a large petrochemical plant where operators managed to boost output by 40 percent simply by rearranging current equipment compartments rather than constructing brand new substations from scratch. The flexibility built into these adaptive systems makes it much easier to bring renewables online too. Many industrial sites are already setting aside roughly a quarter to almost a third of their switchgear space specifically for when they want to connect solar panels or battery storage later down the road.

Precision Power Control and Equipment Longevity

Balancing Loads and Stabilizing Voltage with MV Switchgear

MV switchgear maintains voltage stability within ±2% of nominal levels, even under peak demand. A 2023 EPRI study found that smart MV systems reduced motor burnout incidents by 38% through real-time load balancing. Stable operation prevents insulation degradation, which occurs three times faster under overload conditions.

Case Study: Power Optimization in Automotive Manufacturing

A German automotive plant achieved a 14% energy reduction after installing modular MV switchgear with integrated capacitor banks. The system automatically corrects reactive power, supporting findings from the International Energy Agency that balanced loads extend transformer lifespan by 19%.

Enabling Predictive Maintenance Through Smart MV Switchgear

IoT-enabled sensors in modern MV switchgear detect insulation degradation 6–8 months before failure thresholds. According to the 2023 Grid Reliability Index, predictive maintenance programs using MV analytics reduce unplanned downtime by 72% compared to time-based servicing.

FAQ - Medium Voltage Switchgear

What is Medium Voltage (MV) Switchgear?

Medium Voltage Switchgear is a type of electrical switchgear used in industrial and utility applications to manage electrical power between 1kV and 35kV.

How does MV switchgear improve reliability in industrial power systems?

MV switchgear improves reliability by preventing power instability, reducing downtime, and optimizing redundancy. It detects voltage fluctuations, isolates faults rapidly, and allows seamless power rerouting through redundant configurations.

How does MV switchgear enhance safety?

MV switchgear enhances safety by using arc-resistant designs and advanced sensors that quickly detect faults, minimizing the risk of arc flashes and other electrical hazards.

What are the advantages of using modular MV switchgear?

Modular MV switchgear offers scalability, reduces upgrade costs, and allows easy expansion without significant downtime. It also supports flexible power architectures suitable for future growth and integration with renewable energy sources.

How does MV switchgear contribute to energy efficiency?

MV switchgear operates at higher distribution voltages which results in lower heat loss and energy waste, reducing annual energy losses to 3-5% compared to traditional systems.

EN

EN

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

AR

AR

BG

BG

CS

CS

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

BN

BN

KN

KN

LO

LO

LA

LA

PA

PA

MY

MY

KK

KK

UZ

UZ